Wall Tie Replacement - A Professional Guide.

When wall ties need replacing, the amount of work necessary to restore the structural integrity of your house can seem overwhelming. It need not be so. To help you understand the process better, Twistfix has created a handy 6-part guide. We explain what wall ties are, why they fail and how wall tie replacement systems work. The guide covers the following.

- What are cavity wall ties, and why would your home require wall tie replacement?

- What are the signs and symptoms of wall tie failure?

- What happens during a wall tie corrosion survey?

- How do you retrofit wall ties in existing buildings?

- What types of remedial wall ties are available?

- What factors affect wall tie replacement costs?

What are Cavity Wall Ties?

Cavity walls have been the prime design choice for UK houses for over a century. They have two thin walls, creating an internal and external leaf, with a space between them. Steel strips or wires, known as wall ties, cavity ties or brick ties, link the two walls. The connectors allow the walls to work together as a single unit. When adequately tied, a cavity wall is just as sturdy as a solid wall.

Cavity wall construction prevents damp penetration. It improves thermal efficiency and reduces noise transfer.

Wall ties must secure the outer facade to the load-bearing inner structure. They transfer tension and compression loads and accommodate differential movement between the walls. The ties must also maintain these functions in the event of a fire.

The use of coated mild steel ties was routine in house-building before 1981. Since then, the dominant choice of material is stainless steel. The better-quality steel extends service life and reduces thermal conductivity.

Why do wall ties need replacing?

A building needs new wall ties if the old ones fail to function. Wall tie failure may result from poor construction. It can also be due to rust setting in as the building ages.

- Shoddy construction can result in an inadequate brick tie system. Ties may be scarce in number or too short to suit the width of the cavity. For example, they may lack embedment depth into the mortar. In brick-clad timber frame houses, ties are often fixed into plywood sheathing rather than the structural vertical studs.

- Mild steel building parts deteriorate and become rusty with age. Chemical reactions occur between iron in the steel and moisture in the presence of oxygen. These conditions lead to the onset of wall tie corrosion. The build-up of flakey rust deposits weakens and erodes the metal. Eventually, the wall ties fail.

Regardless of the cause of cavity tie failure, installing a remedial wall tie replacement system will resolve the issue. Retrofit cavity ties secure the outer wall to the main structure of the building. Re-tying the walls will restore stability. New stainless steel ties can share and transfer loads safely.

What are the Signs of Wall Tie Failure?

Building designs differ, as do their wall tie types. Therefore, visible indications of brick-tie problems can vary. There are two significant tell-tale signs to look out for.

- A pattern of horizontal cracks at regular intervals often suggests an issue with wall tie corrosion.

- Bowing walls or wavy external wall surfaces may indicate no connection between the outer and inner walls. Thus, the facade may be free-standing and not supported by the main building structure.

Rust occupies a greater volume of space than the original metal. As corrosion develops, brittle iron oxide layers bulk up the steel strips. Fishtail ties can expand to several times the thickness of the original steel. When repeated along an entire row of steel strip ties, this expansion can create powerful forces that combine to lift and split the wall. The lifting causes a series of horizontal cracks along the hosting mortar beds.

These wall-weakening fractures first appear at higher wall levels. The weight of the brickwork at the top of the wall is less than at its base. Often, ruptures will occur along several mortar bed joints where the rusting ties lay. Typically, the tie rows are 4-8 brick courses apart.

Ties made from thin wire instead of steel strips may lack the mass to produce cracking. The steel can slowly erode with no visual signs of a problem until the wall buckles or bulges.

On rare occasions, wall tie failure can contribute to a wall's collapse in windy conditions. Long spans of brickwork with no structural returns are the areas most vulnerable to high winds. Examples include wall panels between window openings and at the gable apex. So be safe. If you discover any symptoms of wall tie failure, get the walls checked by a professional.

What Does a Wall Tie Corrosion Survey Entail?

During a wall tie inspection, a surveyor will collect data about the wall's construction and its ties' condition. The surveyor uses the survey record objectively to assess the existing wall ties' serviceability.

How to Check Wall Tie Condition and Density.

- Use a metal detector to locate the position of existing ties. Plot the locations over a given wall area to establish the number of existing wall ties per square metre. Check that the tie-density meets current building regulations.

- If the cavity is free from insulation or blockages, use a borescope to inspect the tie portion spanning the cavity.

- Remove a small amount of mortar in the outer leaf to expose tie-ends. The steel section lying in the outer leaf joint is the most vulnerable to moisture. Tie-end inspection establishes wall tie type and its embedment depth.

Identify the Construction Type, Faults, and Exposure.

- Determine the wall makeup on both sides of the cavity. Find out if the walls are of solid bricks, perforated bricks, concrete blocks, or timber frame construction. It helps in selecting the most suitable remedial tie for the building.

- Measure the cavity width at various points to establish the necessary length of replacement ties.

- Note any cracks in the walls and whether they coincide with the positions of the wall ties.

- Record any bowing, leaning, or undulation of wall surfaces.

- List other defects that may relate to the wall ties or contribute to increased corrosion risk.

- Log the site terrain, building height, and its exposure to wind speed per Table 5 of BRE Digest 401.

The surveyor categorises the condition of the ties on a scale ranging from 1 to 9 using Table 2 of BRE Digest 401. The table classifies tie conditions based on visual corrosion levels. Table 4 of the Digest advises the best remedial action given the corrosion scale. The surveyor report must include the BRE advice.

At level 1, the Digest suggests further inspection within the following ten years. At level 9, it recommends immediate wall tie replacement.

How do you Insert Wall Ties in an Existing Building?

If a wall tie replacement program is necessary, a specialist contractor or structural engineer can design a remedial tying system best suited to the building.

Use the decision tree in BRE Digest 329 to establish the best replacement wall ties for various masonry types. Discovering the most suitable remedial tie for a specific structure may involve exploring wall ties with CE Marking or BBA certification. A third-party approval indicates the wall tie complies with British Standards.

The design package should include the following.

Selection of Remedial Wall Tie System.

- Helical wall ties.

- Mechanical expander wall ties.

- Resin fixed wall ties.

Wall Tie Spacing and Number of Ties per Square Metre.

- Use 2.5 ties per sqm where both walls are masonry and are more than 90 mm thick.

- Use 5.0 ties per sqm where at least one masonry wall is less than 90 mm thick.

- Use 4.4 ties per sqm where the inner wall is of timber-frame construction.

Wall Tie Testing.

- Determine the sampling rates for testing new wall ties.

- Establish the required tensile proof load values following Table 5 of BRE Digest 401.

Preventing Damage from Corroding Ties.

- No action is necessary.

- Isolate the part of the tie that sits in the outer wall layer.

- Remove the tie from both the inner and outer walls.

Patching After Inserting Replacement Wall Ties.

- Plug drill holes to colour-match the brickwork.

- Rake out and deeply repoint cracked mortar bed joints.

- Repair renders, leaving ready for decoration.

Advisories to Repair, Protect, or Stabilise the Wall.

- General repointing.

- Masonry crack repair.

- Lateral restraint.

- Weatherproofing.

- Cavity cleaning.

What Remedial Wall Tie Types are Available?

What are Helical Wall Ties?

Helical wall ties are work-hardened stainless-steel wires. The ties are cold-rolled into a cruciform shape before being twisted. They are used to anchor the outer wall of a building to its inner structure. The ties come in different lengths to suit various cavity widths.

How do Helical Wall Ties Work?

A setting tool in an SDS hammer drill delivers lightweight blows to one end of the tie. The hammer action drives the 9 mm helical wall tie into a smaller pilot hole. The tie's shape causes it to rotate and screw into masonry or concrete following its helix angle. Work-hardened threads cut grooves into brickwork as they advance into the hole. The helical tie grips the masonry on both sides of the cavity. The helix provides multiple drip points across the cavity to prevent water transfer.

Helical wall ties are quick and easy to fix. They withstand axial loads and are suitable for brick, block and concrete structures. The ties are ideal for buildings requiring a fire rating.

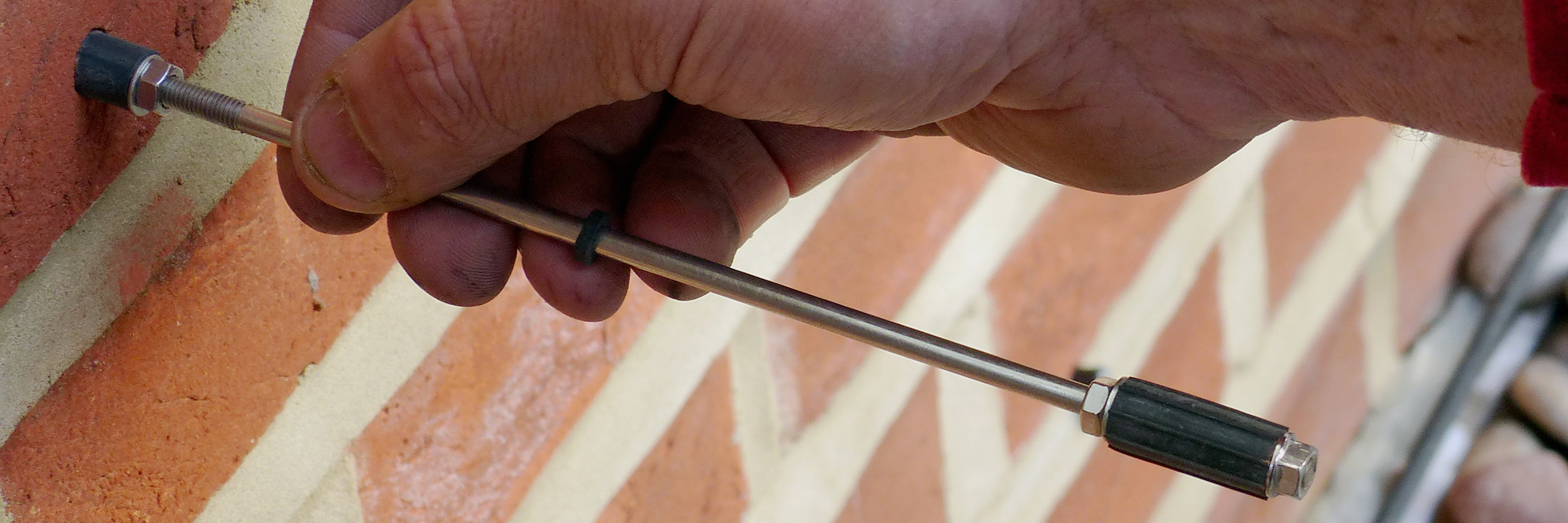

What are Mechanical Wall Ties?

Mechanical wall ties are stainless steel threaded studs with an expanding mechanism at each end. The expansion mechanisms include a radially expanding sleeve held firmly between nuts and washers. Several sizes are available to suit the most common cavity widths.

How do Mechanical Expanding Wall Ties Work?

A mechanically expanding wall tie fits into a pre-drilled clearance hole. Turning the torque nut clockwise causes the tie bar to rotate. The mechanism squashes the neoprene sleeve between the nuts and washers at the far end of the tie. The compressed neoprene sleeve expands radially, tightly gripping inside the hole in the internal wall.

At a factory-set torque level, the part-threaded torque nut winds down the stud. It forces the other sleeve to engage and grip the external wall. Mechanical ties have a central neoprene drip ring. The 'O'-ring stops water transfer across the cavity.

What are Resin Fix Wall Ties?

Resin-fix wall ties are pins made from stainless steel. They have uneven surface that bonds well with resin construction adhesives. The pins may be simple threaded studs, helically twisted bars or even stainless steel rebars.

How do Resin Fix Wall Ties Work?

Use compressed air to remove all dust and residue from pre-formed clearance holes. Inject resin into the inner-leaf bore and push the tie-bar into the adhesive. Once the inner wall adhesive sets, dispense resin around the section of the tie in the external wall. It cures to form the facade connection and complete the anchoring process.

How Much Does Wall Tie Replacement Cost?

Stainless steel remedial wall ties are relatively inexpensive. Still, the cost of a wall tie replacement scheme depends on numerous factors. A contractor's price may include the following.

- The cost of scaffolding necessary to work safely at heights.

- The quantity and length of the replacement ties.

- The cost of specialist insertion tools.

- The number of ties that need to be isolated or removed.

- The type and extent of repairs necessary to camouflage the wall tie replacement work.

An expert builder or specialist contractor will find most replacement tie systems quick and easy to fit. If you are competent in DIY, you can save money by doing the work yourself. However, you must follow all tying and testing instructions.

Twistfix supplies a range of professional wall tie replacement kits. Use our wall tie calculator to determine how many remedial ties you need. You can browse our website to find high-quality tying solutions at competitive prices. If in doubt about any wall tie replacement scheme, call our technical team for clear-cut, expert advice.

Related documents.

![]() How to fit Mechanically-Expanding Brick Ties.

How to fit Mechanically-Expanding Brick Ties.

![]() How to install Resin-fix Cavity Ties.

How to install Resin-fix Cavity Ties.

![]() Wall Tie Spacing Pattern at 2.5 Ties per M2.

Wall Tie Spacing Pattern at 2.5 Ties per M2.